The making of a healthy energy efficient home

This healthy home renovation will be featured during Green Energy Doors Open, September 10. For details and to register visit: greenenergydoorsopen.ca/events/bertmount-healthy-home-retrofit

Houses are becoming more energy efficient than ever before. They will become even tighter due to changes to Ontario’s Building Code, which come into effect in January. This is good. The more airtight the building, the less reliant we are on fossil fuels to heat and cool them.

There’s a catch, however.

Since the late 1980s, thousands of chemicals have been incorporated into building materials and other products that enter the home, according to Paula Baker-Laporte in her book, Prescriptions for a Healthy Home. In today’s typical house, air is exchanged once every five hours when once it was exchanged once an hour. The typical North American now also spends about 90% of their lives indoors.

It’s bad enough for most people to inhale off-gassing chemicals, but for those who have chemical sensitivities, this toxic brew can be debilitating. This is certainly the case for our client in Toronto’s Leslieville neighbourhood, who has Mast Cell Activation Disorder (MCAD).

At Greening Homes we’ve made it standard practice to regularly consult the International Living Future Institute’s Red List and Declare, which identify toxic chemicals lurking in building materials. Reducing a home’s toxic load is a priority for Greening Homes’ president, Christopher Phillips, who has a Master’s Degree in Building Science from Ryerson University with a focus on building materials and health impacts. Phillips and the crew keep abreast of the latest innovations in non-toxic and energy efficient building materials by attending frequent seminars and attending events such as the upcoming Living Products Expo, being held in Pittsburgh from September 13-15. Several clients have turned to us specifically for our expertise in healthy home renovations and multiple chemical sensitivity design consultations.

“The Bertmount project in Leslieville is special because we went through a process from the very beginning – to understand the client’s very specific health concerns,” says Phillips. “We took a look at every single building impact on [the client’s] heath to design and specify materials and approaches to minimize those health impacts.”

Those with MCAD have an exaggerated number of mast cells. Certain triggers can cause these mast cells to release substances into the body, resulting in a number of symptoms that can include lightheadedness, short term memory, wheezing, fatigue, difficulty breathing and gastrointestinal problems.

Triggers can be very subjective and sometimes unidentifiable, which presented us with a challenge. Some triggers, however, like mould, volatile organic compounds (VOCs), aldehydes, sunlight and temperature extremes are very common.

Mr. Phillips borrowed heavily from his formal training. He spent several weeks researching the condition and how triggers for MCAD could be reduced in building materials across the renovation. The result was a comprehensive site and client-specific pre-renovation report of recommended best practices that the clients were excited to implement.

The full retrofit of this 100-year-old home began in 2015. Renovation work on the Bertmount house was done prior to Greening Homes’ involvement, but it had to be completely gutted for various reasons, including the use of client-inappropriate materials, such as spray foam.

Unfortunately it’s not unheard of for homeowners to redo renovations because the building materials impact their health, causing symptoms that range from rashes, headaches, eye irritations to more serious conditions like chronic cough, chronic sinus infections, joint and muscle pain, memory loss, fatigue, anxiety, depressions and allergies.

Just as our Beechwood renovation gave us the opportunity to develop one of the highest performing homes in Canada with healthy building products, the Bertmount project is an exciting opportunity to develop one of the country’s healthiest energy efficient homes.

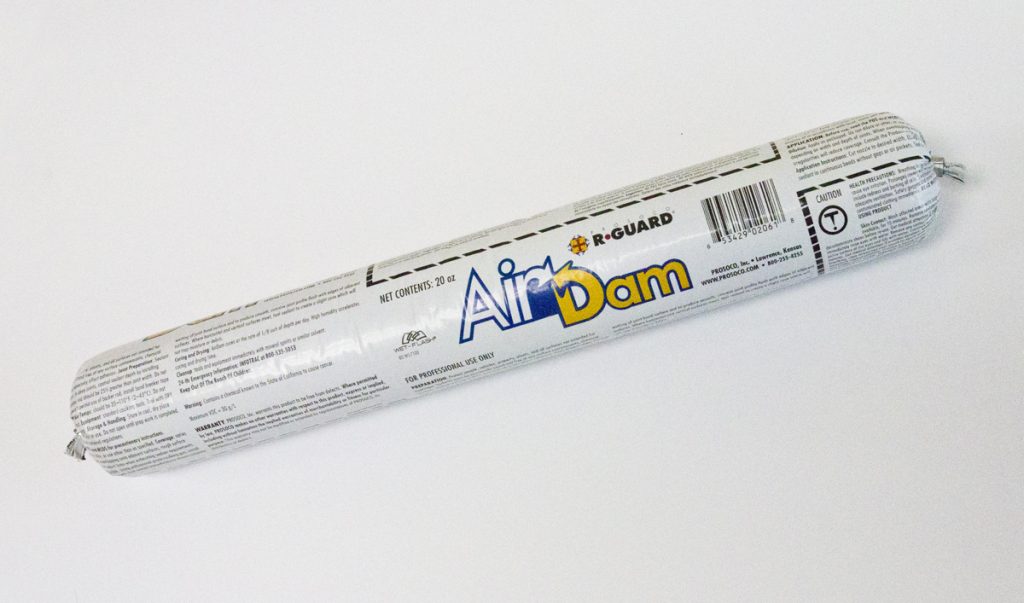

The homeowner was willing to work with our team to use the relatively new cutting-edge products such as Prosoco R-Guard AirDam, a Red List-free wet-applied product with great adhesive qualities. The product was so new, it wasn’t available in our region – until now. In order to access the product, Greening Homes became the local distributor. It is now our go-to subfloor adhesive, and used as a standard product across all our renovations. For more on the nontoxic products used during this project, visit our blog, Building healthy homes through non-toxic construction adhesives.

Choice of insulation was also very important. We needed a material that could offer a strong R-value – a measure of thermal resistance – with zero chemicals. Spray foam was off the table. Petro-chemical based foam insulations generally deliver the highest R-values per inch, but often have high embodied energy, ozone depleting potential, and the possibility of persistent environmental toxicity that pose potential adverse effects on the occupants and environmental health. Even Roxul’s excellent mineral wool insulation is manufactured with six percent formaldehyde binder. While this potential carcinogen is mostly burned off in the process of making the insulation, we couldn’t afford the risk of placing it in the walls. We did, however, use a Roxul product below our basement slab in place of typical XPS foam, a standard practice for us which is generally unique in our industry.

We elected to use dense-packed cellulose insulation for our walls in this project, including below grade. The reasons are clear: the material has a high recycled content, low embodied energy, it emits no VOCs, and it does not contain petroleum products. For more on this, visit our blog: Installing dense-packed cellulose in newly-framed walls.

Another product we’ve been eager to use is the CertainTeed AirRenew drywall. This drywall encapsulates formaldehyde molecules into its matrix, literally cleansing the air! We’ve installed this product to help minimize any trailing impacts from our renovation, and also to help reduce future impacts of aldehydes that may be contained in materials brought into the home (in furniture, for example).

We also used Thermory Ash, a chemical-free, FSC-certified, durable decking wood, for the first time on a home renovation. We used it recently for planters and benches that we built for Eva’s Initiatives’ new home for at-risk youth, as part of the Canadian Green Building Council’s Legacy project.

Thermory Ash is slowly heated, which releases natural preservatives to create an environmentally preferable alternative to chemically-treated lumber. For the deck we chose it over cedar, which — like other aromatic woods — contains natural (but mildly toxic) terpenes that can be a trigger for some people with chemical sensitivities.

Some other healthy and green features include:

A radiant mechanical system rather than forced-air, which recirculates air and spreads fine particles. The basement slab, first floor and washroom floors use Warmboard. To learn more about Warmboard, visit our blog: Choosing Warmboard for this reno’s radiant floors.

The remaining rooms are heated by radiators. Fresh air is delivered to living spaces through an Energy Recovery Ventilator (ERV) while stale air is exhausted from the washrooms, kitchen and laundry room. Although supplying 100 percent outdoor air is generally regarded as the best way to ensure high indoor air quality, this project goes a step further by filtering the outdoor air using HEPA filtration in line with the ERV. Cooling is supplied by a multi-head heat pump system. The point source cooling allows individual control in the bedrooms.

Lights and receptacles are wired through a master switch in the master bedroom, creating a safe zone in the bedroom so that these EMFs can be quickly turned off if they are found to be aggravating the home owner’s condition.

The home’s water treatment system consists of a whole-house water softener, while drinking water is subjected to reverse-osmosis filtration.

A cool roofing membrane was installed on the new flat roof to mitigate summer heat gain and the urban heat island effect. The roofing system was cold-applied. We used a zero-VOC primer to reduce fumes and undesirable odours during installation.

Interior zero-VOC paint – Natura by Benjamin Moore or YOLO BY Colorhouse.

Where applicable, a “smart” below grade vapour retarder, such as Certainteed MemBRAIN, was used over typical 6 mil poly, as it contains two-way drying potential that acts in concert with vapour pressure.

Natural linseed oil – Rubio Monocoat – used for solid walnut stairs pre-finish.

Recycled denim batt used for sound attenuating insulation.

Lumber is FSC certified where possible.

Re-use of salvaged structural lumber. For more visit our blog: Saving material, energy and money – Greening Homes’ core pillars in action.

Double glazed aluminum-clad windows above grade and double glazed fibreglass framed windows below grade (avoiding vinyl, as per company policy).

Unique high-performance window installation methodology, with expanding foam tape and u-shims.

Kitchen cabinet carcasses are NAUF plywood with solid wood doors, finished with a low-VOC, water-based lacquer.

Visit Greening Homes’ Bertmount renovation on September 10 during Green Energy Doors Open! For details and to register, visit: greenenergydoorsopen.ca/events/bertmount-healthy-home-retrofit